Solutions for mezcal producers Our contribution to agave's magic

We need to change!

Despite being only 1% of the tequila production, due to its characteristics, mezcal is growing exponentially to become a favorite drink in the world. We are definitely pleased with that, however we also show concern for the artisanal production techniques that are not ready for larger volumes: vinazas (a toxic bi-product from the residues of distillation) and the abuse of firewood have to be overcome with technical solutions if we want to have a sustainable production.

Our ovens allow more than 40% of savings in energy, and our biodigester aims to solve the vinaza situation. Follow us for more!

Highlights

Energy saving

Our EG gas burners (patent in process) save up to 40% in LP Gas, compared to conventional ovens. They are also methanol prepared.

Temperature control

Our ovens include a control panel that allows a much more accurate and controlled production.

Heat recycling

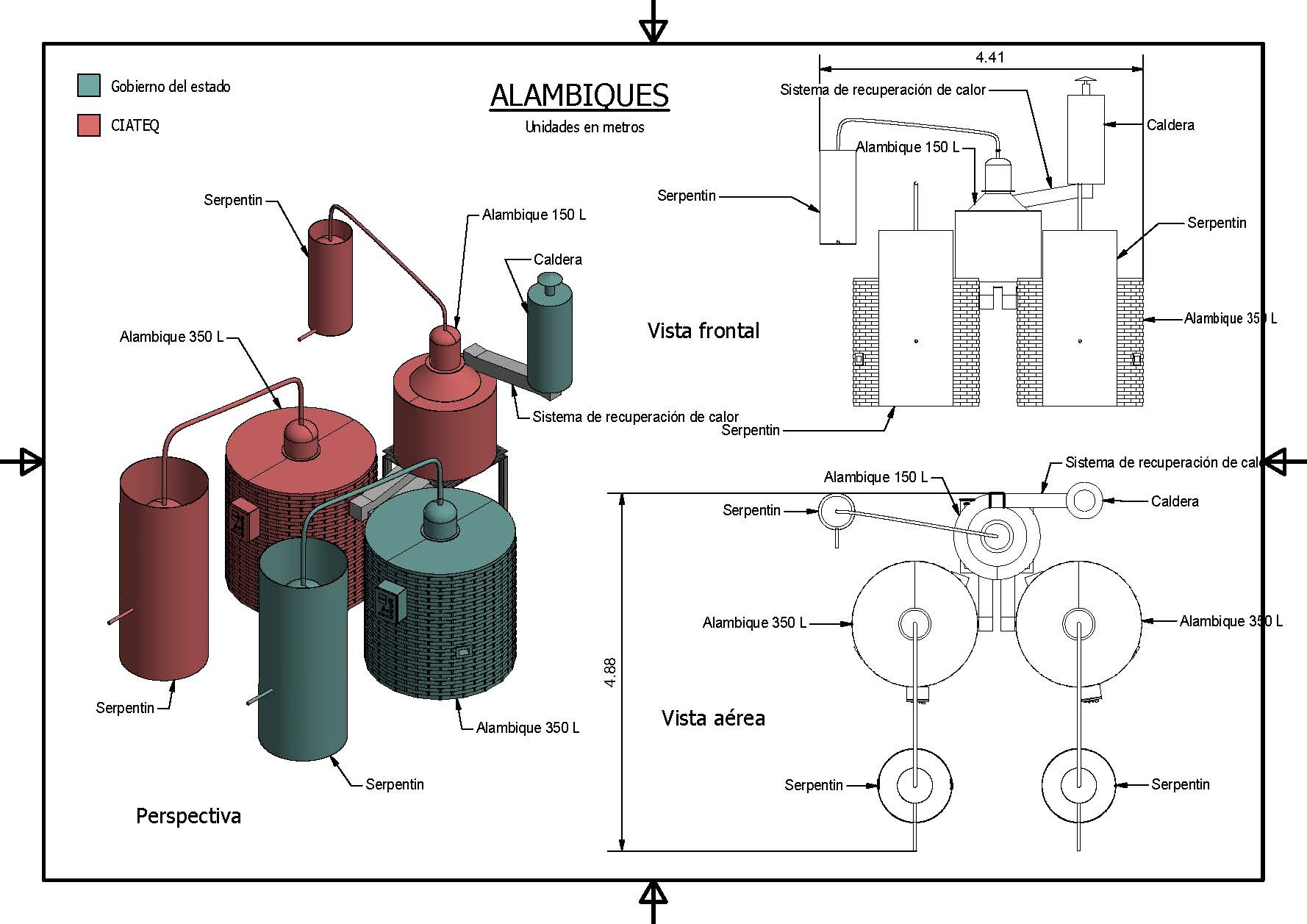

The heat that emanates from the ovens during the first phase of the distillation process can be used during the second distillation too, thus saving a lot of energy.

Flexibility

Our ovens have a modular form, so that they can fit in to your specific needs for sizes and capacities.

EFFICIENT BURNERS

Our EG burners received the ADIAT (Mexican Association of Directors in Applied Research and Technological Development) prize in 2014.

Technology and Security

- Refractory materials: isolates oven interior = energetic efficiency.

- We build the ovens and install combustion systems.

- Control Panel with sensors, thermometers and System valves = Automatization of distillation process.

- Flame UV Sensor and Reader: If flame fails, systems sends a valve closing alert to the Control Panel

- In the case of absence of electricity, solenoidal valves interrupt gas flux. PPX Technology includes security.

- Industrial thermometer (Termopar: Ceramic for high temperature) = High Precision Temperature Monitoring

Solutions for mezcal producers Our contribution to agave's magic

We need to change!

Despite being only 1% of the tequila production, due to its characteristics, mezcal is growing exponentially to become a favorite drink in the world. We are definitely pleased with that, however we also show concern for the artisanal production techniques that are not ready for larger volumes: vinazas (a toxic bi-product from the residues of distillation) and the abuse of firewood have to be overcome with technical solutions if we want to have a sustainable production.

Our ovens allow more than 40% of savings in energy, and our biodigester aims to solve the vinaza situation. Follow us for more!

Highlights

Energy saving

Our EG gas burners (patent in process) save up to 40% in LP Gas, compared to conventional ovens. They are also methanol prepared.

Temperature control

Our ovens include a control panel that allows a much more accurate and controlled production.

Heat recycling

The heat that emanates from the ovens during the first phase of the distillation process can be used during the second distillation too, thus saving a lot of energy.

Flexibility

Our ovens have a modular form, so that they can fit in to your specific needs for sizes and capacities.

EFFICIENT BURNERS

Our EG burners received the ADIAT (Mexican Association of Directors in Applied Research and Technological Development) prize in 2014.

Technology and Security

- Refractory materials: isolates oven interior = energetic efficiency.

- We build the ovens and install combustion systems.

- Control Panel with sensors, thermometers and System valves = Automatization of distillation process.

- Flame UV Sensor and Reader: If flame fails, systems sends a valve closing alert to the Control Panel

- In the case of absence of electricity, solenoidal valves interrupt gas flux. PPX Technology includes security.

- Industrial thermometer (Termopar: Ceramic for high temperature) = High Precision Temperature Monitoring

Solutions for mezcal producers Our contribution to agave's magic

We need to change!

Despite being only 1% of the tequila production, due to its characteristics, mezcal is growing exponentially to become a favorite drink in the world. We are definitely pleased with that, however we also show concern for the artisanal production techniques that are not ready for larger volumes: vinazas (a toxic bi-product from the residues of distillation) and the abuse of firewood have to be overcome with technical solutions if we want to have a sustainable production.

Our ovens allow more than 40% of savings in energy, and our biodigester aims to solve the vinaza situation. Follow us for more!

Algunas características

Energy saving

NOur EG gas burners (patent in process) save up to 40% in LP Gas, compared to conventional ovens. They are also methanol prepared.

Temperature control

Our ovens include a control panel that allows a much more accurate and controlled production.

Heat recycling

The heat that emanates from the ovens during the first phase of the distillation process can be used during the second distillation too, thus saving a lot of energy.

Flexibility

Our ovens have a modular form, so that they can fit in to your specific needs for sizes and capacities.